.jpg)

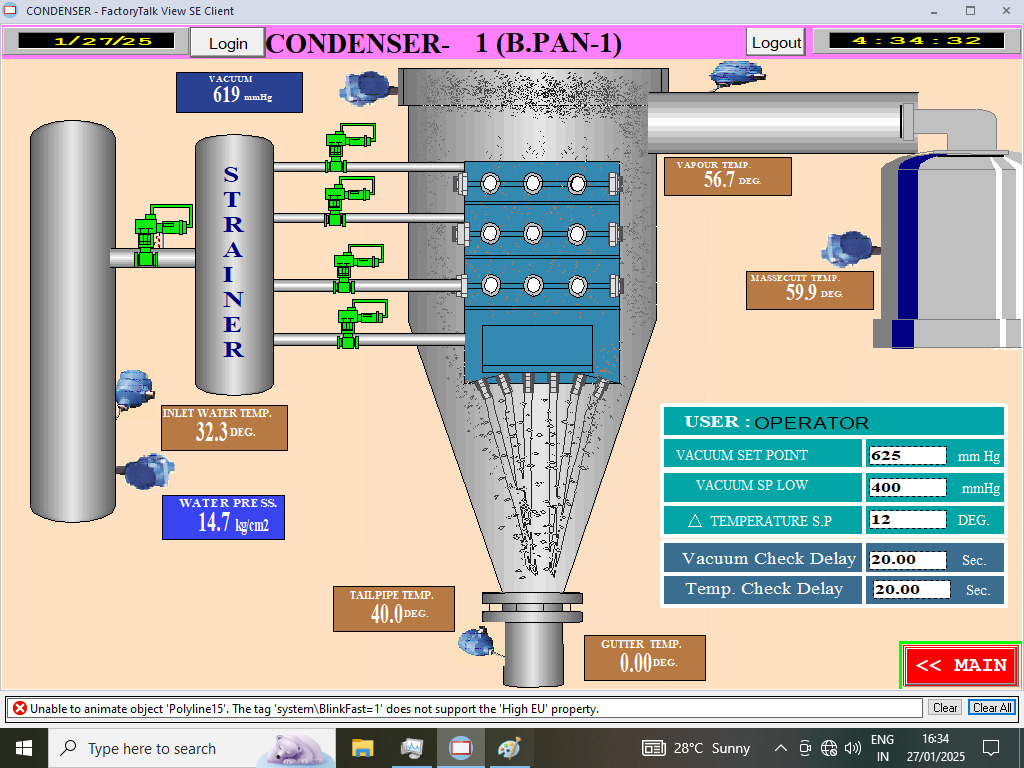

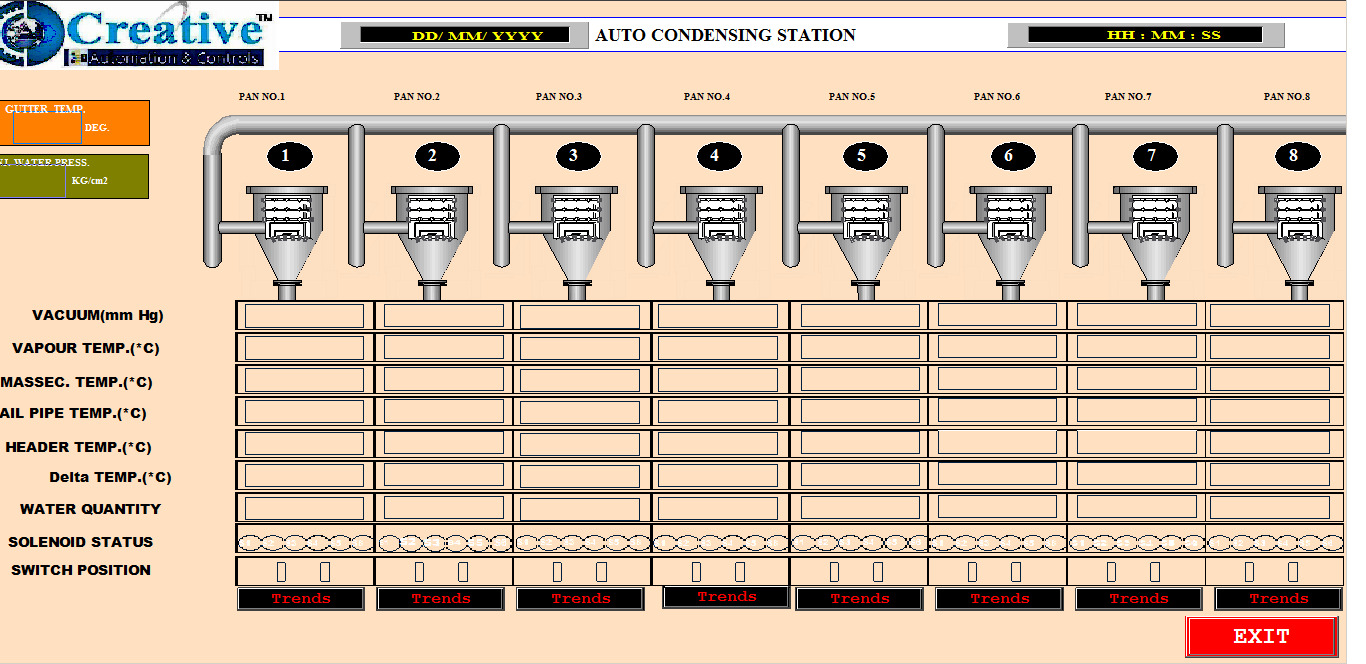

Condenser Automation

Benefits of Condenser Automation

- Enhanced Energy Efficiency: Stable vacuum control ensures uniform operation of evaporators and pans

- Reduced Operational Costs: Reduced energy and water consumption through optimized cooling operations

- Centralized Monitoring: Centralized monitoring and control via SCADA improves reliability

- Data-Driven Decisions:Real-time fault detection and automated corrective action reduce system downtime